In 2024, Pathfinder Tonopah completed a PEA on the property that integrates historically mined supergene copper resources and hypogene molybdenum-focused resources into a single mine project plan. This flow sheet provides flexibility to transition from supergene copper resources into hypogene resources with only minor modifications to the process configuration. The process flow sheet uses floatation in conjunction with known leaching methods that yields copper cathode and a molybdenum concentrate.

There is opportunity for the project to develop a facility that produces a higher-value molybdenum product on-site and that could serve as a regional toll-processing facility.

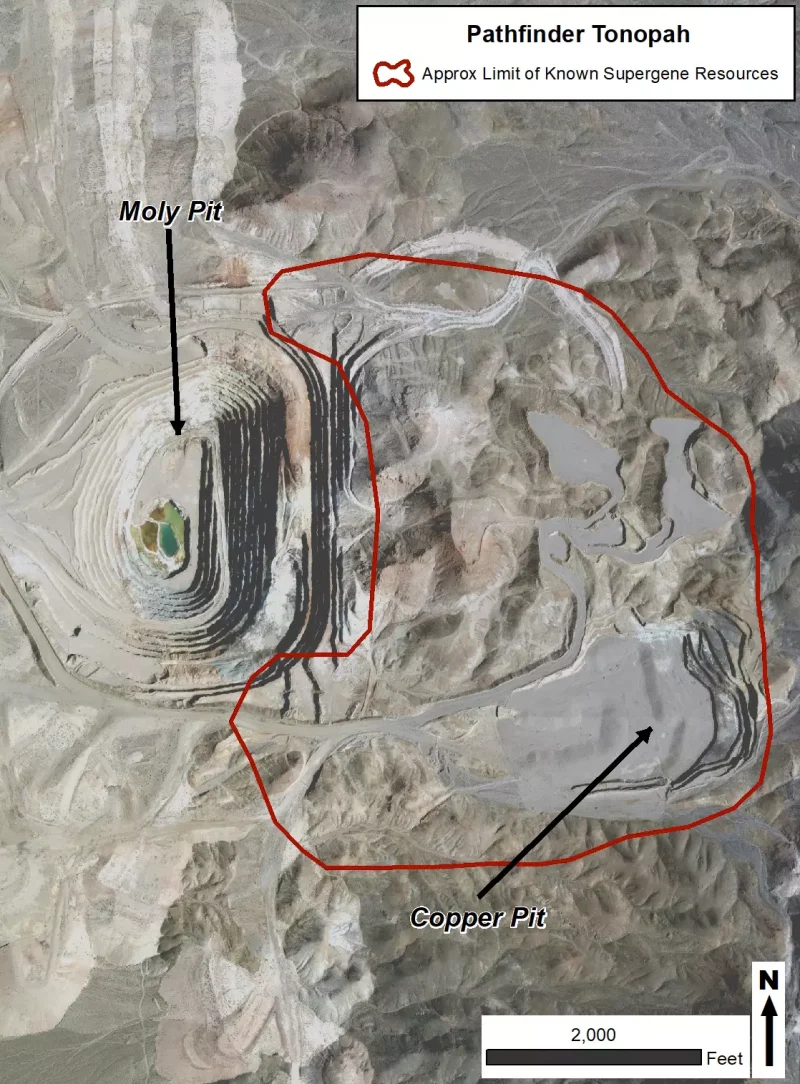

The updated Mineral Resources are predominantly on private property, which allows for the first portion of the mine plan to be on private land and to be permitted through Nevada state agencies. The site also benefits from in-tact infrastructure utilized by previous mine operators, including roads, power access, water-rights, office and maintenance buildings, and other infrastructure.

Pathfinder has started work on a Definitive Feasibility Study (DFS) that builds on a large body of technical studies already completed on most aspects of the project. Work programs for the DFS will refine facets of the project including pit-slope constraints, mine planning and fleet requirements, tailings and waste management, facility specifications, water monitoring and management, and metallurgical processes for supergene copper and hypogene molybdenum resources.

Pathfinder believes this project provides a unique opportunity to bring a copper project online efficiently, responsibly and expediently in a favorable jurisdiction.

Following results from tests completed with experts from three separate leading global firms, Pathfinder has developed a metallurgical process flow sheet that recovers the best value from the copper and molybdenum utilizing both flotation and vat leaching. A bulk sulfide concentrate will be leached in a standard acid vat to extract soluble copper, that will be recovered as cathode. Residue from the leaching will be sent through cleaning circuits to recover molybdenum as a molybdenite concentrate. These well-known and effective processes will allow for treatment of both supergene and hypogene resources through the life of the mine retaining flexibility to blend resources with minimal modifications to the flow sheet.

The Complex was historically mined in the 1980’s and early 1990’s by Anaconda and later Cyprus for molybdenum, mainly within the hypogene porphyry system. In total, approximately 29 million tons of ore were processed to yield about 53 million pounds of molybdenum.

In the late 1990’s and early 2000’s, Equatorial Tonopah mined a portion of the supergene copper blanket, which was largely hosted in mineralized meta-sediments. Over 14 million tons of supergene ore were mined and heap leached.

Notes:

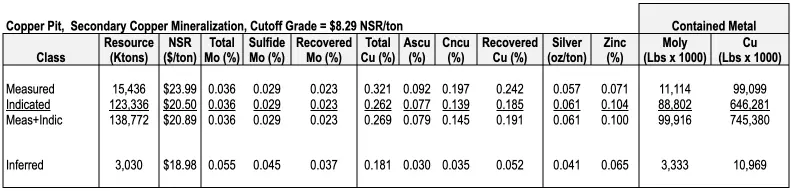

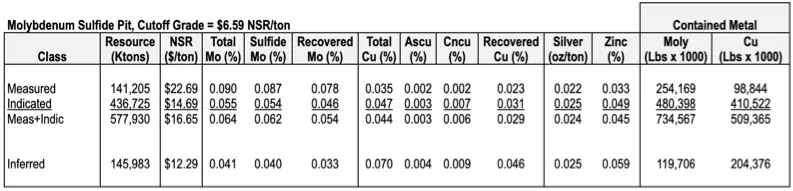

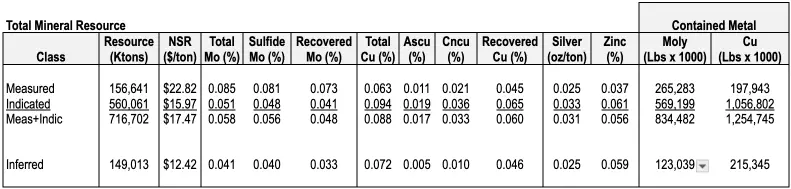

The updated Mineral Resource shows that the bulk of the known in-situ resources, both hypogene molybdenum and supergene copper resources, remain unmined. Because portions of both the supergene and hypogene resources were mined historically, early phases of mining will require minimal development work, and we expect the strip ratio for the supergene copper resources over the first 10 years will be about 0.75:1.

The mine schedule and plan developed for the 2024 PEA considered a throughput of approximately 10 million tons of ore per year. At this production rate, the first 12 years of mining would focus on the supergene copper resources and produce over 463 million pounds of copper cathode. Trade-off analyses of increasing the throughput to approximately 20 million tons of ore per year indicated better project economics by

simultaneously mining supergene and hypogene material. This higher throughput would result in a mine life of approximately 24 years to produce about 600 million pound of copper and about 500 million pounds of molybdenum. Though the higher-throughput mine plan only considers processing about 404 million tons of ore, the Mineral Resource Estimate identified over 716 million tons of Measured and Indicated Resources, which illustrates the potential the project has for continued production.

The Hall Mine Complex is centered on a porphyry Cu-Mo system in the western flanks of the San Antonio Mountains. The Hall Stock is a multi-phase, southeasterly plunging quartz monzonite porphyry (66-70 Ma) that hosts much of the Cu-Mo mineralization. The porphyry intrudes a metamorphosed package of Late Paleozoic to Early Mesozoic sediments that have been variably mineralized by the porphyry system. Tertiary dikes and volcanics cut the porphyry mineralization, and some of these later intrusive bodies appear to be associated with later, structurally controlled silver mineralization.

Basin and range faults cut portions of the system. One of the more prominent structures is the northerly striking Liberty Fault, which dips to the west at ~40° and truncates the porphyry system to the West, bringing mineralized basement rock up against basin-fill alluvium and colluvium. Uplift and weathering of the Cu-Mo porphyry system resulted in the development of a near-surface and near-horizontal supergene copper blanket.

Mineralization in the hypogene Cu-Mo porphyry is dominated by molybdenite (MoS2) and chalcopyrite (CuFeS2). The dominant copper mineral in the supergene blanket is chalcocite (Cu2S) with minor chalcopyrite.